An auger plays a vital role inside the lives of those when it comes to digging out a dent. It has become a great item of equipment that speeds up the digging process. Hence, the obsolete way of employing human physical force for excavation may be gradually eradicated and replaced by this powerful tool.

An auger can be utilized in a number of activities such as gardening, digging holes for fence posts, tree planting, excavating holes for electrical and telecommunication posts and in many cases for mining activities. Today, this machine is required differently nevertheless for one ultimate purpose and that’s to bore holes.

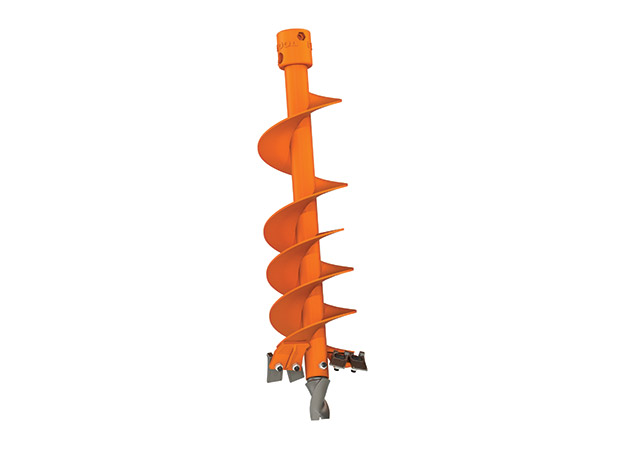

Basically, an auger can be a device with a helical-shaped bit. The spiral kind of this bit of boring devices are the main reason why it can develop a cylindrical hole. Let us take a closer look.

It’s made up of different parts which form and complete its function. It provides a cutting point along with a leading edge in the tip, the first part to penetrate touch using the material that requires drilling. The cutting point along with the cutting edge must be perfectly centered in each application to create a perfect cylindrical hole. The tip of the drill bit includes a different point style based on the task available. The angle in the cutting point determines how the bit can easily dig into the materials being bored.

The helical model of the auger is named spiral flute which channels filings or waste materials upward. The spiral shape typically has two cutting edges that move around the shank and shave materials while at the same time assist in the removing of the chips. In the hole-making operations, the drill bit enters the job piece axially and cuts a dent through with a diameter add up to that of the bit. The cylindrical hole may be accomplished through the use of downward force and clockwise rotational movement around the auger to enter the top.

The alternative in the cutting point may be the drill head which is commonly that come with a holding device known as a collet. This holding device can exert a solid clamping force for the borer to carry it available.

For demonstration purposes, let’s utilize obsolete though useful boring instrument called a brace and bit to describe how an auger works. Just imagine that the device features a drill bit linked to the brace using a u-shaped body used to rotate the tool and a wood spindle where downward pressure can be applied. Now, grab a piece of wood and lay it with a flat workiing surace in order to find the prospective. Shoot for the mark using the cutting point of the drill bit and squeeze device perpendicular towards the wooden piece. Do not forget that pengo attachments for sale is the hand-driven drill; the mechanics on this equipment is to make use of hand effort to use a downward force at the top spindle and rotate the device counter-clockwise while using the u-shaped grip to get in the wood. More sweats should be drained to create 100 revolutions each minute.

Now you must to utilize the powered auger. Select the size to be used and hook it over a power head. A powered auger works extremely well by either worker in the two of workers depending on the type of power head. Using this type of heightened technological advancement to augers, a dent could be dug along with a task carried out in moments instead of hours. This product can rotate 150 rpm or more depending on the power head being using. This will likely definitely saving time and.

To get more information about pengo rock auger teeth for sale web page: visit site.